CNC gear grinding machine for Northwest Gears - When Boeing designed the wings on the 757 and the 777

they had no idea how difficult it was going to be to find a vendor that was able to produce the sector

gears used to drive the slats forward.

The design of the wings was brilliant. They were thinner and longer than previous wing designs so the

glide ratio was much more efficient, thus using less fuel. The trouble was, the thin wings could

no longer hold the bulky mechanisms that were used on earlier slat drives.

Their solution involved thin, arched, highly loaded sector gears. Great concept, but after two

companies went bankrupt trying to figure out how to make them, Boeing was nervous. They turned

to one of their "golden child" companies, Northwest Gears. We had a reputation for being able to

do anything, but we were not cheap.

Anyway, the owners turned to me with a fistfull of cash and said "figure it out". I and my group

went to work and designed an entire manufacturing process which included a customized gear cutter,

heat treat quenching machine, inspection machines, and a custom-built CNC gear grinder.

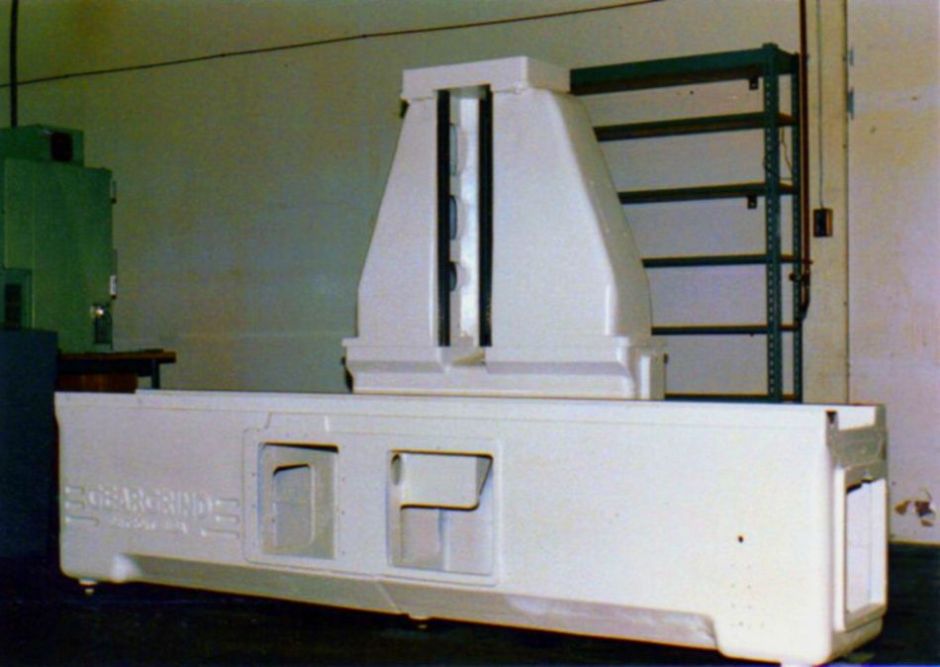

We started with a Detroit Gear Grinder chassis. It was completely remachined and all ways were

hand scraped back into a perfect fit.

The entire development process took a little less than one year. The first production run had a 96% success

rate. In six months the cash flow was so good that I was completely forgiven for going 20% over budget.

Two years later the owners happily sold the company to an Airbus subcompany. Seems that Airbus

wanted the process too.

|