College senior design project - I convinced myself that I could carry a full load for my senior year and build

a complete car for my design project. Needless to say, two semesters became four.

The major components came together as planned in a reasonable amount of time, but the detail work caught

me off guard. "Silly" things like a fuel gauge that didn't bounce all over the place and wipers that cleared

the correct amount of windshield. Every detail had to be figured out, and then redone when the first (or second)

attempt didn't quite work out.

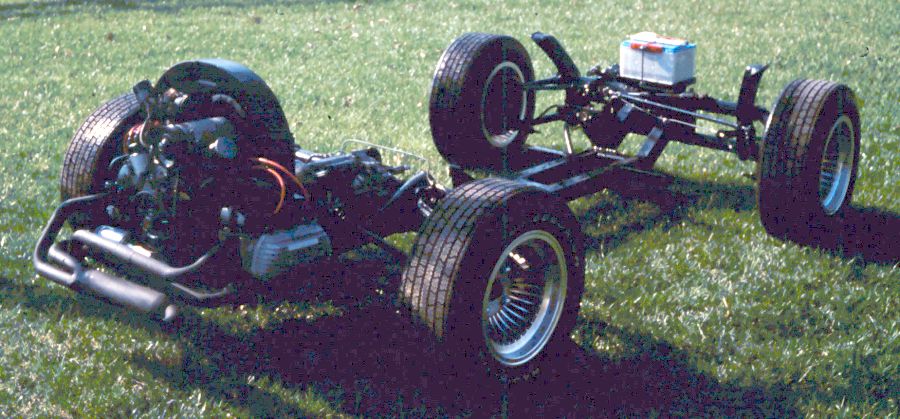

The drive and suspension components all came from a VW Beetle. The chassis was a simple ladder frame

made from mild steel tubing.

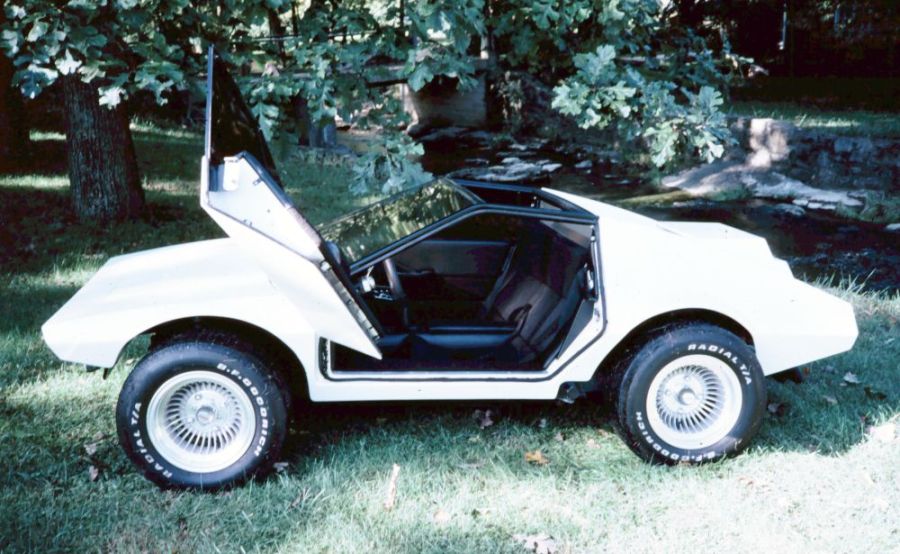

The body was made from fiberglass. Rather than glassing over foam like most one-offs, I decided go with the

plug-mold-part process. I wanted to experience the entire plug-to-part production cycle. Again, it was more

than I bargained for, but still worth it.

The mold had to be a break-apart mold to get around all of the corners, which was another real learning

experience (and frustration). After the mold was complete, a friend of mine and I took the plug to the dump

and smashed it to pieces with sledge hammers. Very cathartic.

The roof frame was made from mild steel. The front window was made from tinted auto safety glass. The side and

rear windows were made from tinted Lexan.

The doors were tricky because I wanted hidden hinges, and I had not designed them when I made the body. Silly,

but at the time, I figured that it would not be a big issue, that it would just work out. I now know that nothing

just works out. Everything needs to be planned out before you start.

It was a great learning experience. I drove the car for about a year. I finally sold it to a radio disc jockey in

Nashville ... ready for the next design project!

P.S. I received an A on the project.

|